Steam is one of the necessary energy sources for textile printing and dyeing production process. The steam comes from a steam boiler. The fuel for steam boilers usually includes coal, oil, gas and biomass. The most commonly used fuel is coal.

As the society has higher and higher requirements for environmental protection, especially the deepening of the prevention and control of air pollution, it is a general trend for textile printing and dyeing enterprises to replace coal as the fuel of steam boilers with gas.

In the future, gas-fired boilers will be widely used and promoted in industrial manufacturing industry. However, whether natural gas or liquefied gas is used, its price is several times higher than that of coal.

The replacement of coal with gas is not a simple energy replacement problem or a problem of equipment replacement. It is a matter of in-depth and meticulous energy-saving work for textile printing and dyeing enterprises to increase the utilization rate of heat energy and reduce the loss of heat energy during the replacement process, so as to achieve Economically, it can withstand the economic pressure caused by the increase in fuel prices. This requires not only the selection of energy-efficient gas boilers and steam-consuming equipment, but also the reasonable design, strict management and serious maintenance of the entire steam system, and to strengthen the management of steam and the improvement of the corresponding process flow.

Practice show that,through comprehensive transformation and improvement, it is possible to meet the requirements of environmental protection in the process of using gas-fired boilers, and to enable enterprises to withstand the cost pressure caused by rising fuels.

There is a medium-sized knitting dyeing and finishing company. The products produced by the factory are mainly cotton, polyester and polyester/cotton blended knitted fabrics. The designed annual production capacity is 15,000 tons. The dyeing production process is mainly the dip dyeing process, combined with open-width scouring and bleaching. And water washing, cold pile pretreatment and other processes. The production process includes post-finishing such as pre-forming, scouring and bleaching, dyeing, setting and softening.

The following is a comprehensive summary of the use of the plant's gas-fired boiler, the design and management of steam system, and the corresponding technological reforms.

Steam System

Steam System Composition

As you can see from the figure, the entire steam system can be divided into the following parts:

1. Steam production part: It is composed of gas boiler, soft water treatment system, deaeration tank, water preheater, air preheater and related fan and water pump.

2. Steam delivery and distribution part: it is composed of steam pipelines, valves, heat storage tanks and temperature reducing and pressure reducing devices.

3. Steam use and consumption part: it consists of production equipment such as dyeing machine, setting machine, dryer, flat-spoke washing machine and so on.

4. Steam recovery and utilization part: steam waste heat recovery system of setting machine, including flash tank, etc.; condensate waste heat recovery system.

Main Indicators

1. Design technical indicators of steam boiler

project | Technical index | project | Technical index |

Design fuel | Natural gas | Boiler outlet medium | superheated steam |

Outlet steam temprature | 400℃ | Rated pressure | 2.5MPa |

Burner | Low nitrogen burner | rated output | 12000kg/h |

Design thermal efficiency | 95.9% | Exhaust smoke temperature | 85.40℃ |

Fuel consumption | 094.103nn | Stable operating conditions range | 80-100% |

Burner fan | 45kW | Boiler feed water | 55kW |

Project Technical index project Technical index

In the actual production process, the amount of steam is generated according to needs, and the temperature and pressure of the steam must be guaranteed.

2. Technical indicators of production equipment

Production equipment, including dyeing machines, setting machines, dryers and other consumption equipment.

NO. | Technical index | Dyeing machine | Drying machine | Other steam-consuming equipment | Shaping machine |

1 | Maximum operating temperature(℃) | 130 | 110 | 120 | 200 |

2 | steam temperature(℃) | ≤150 | ≤150 | ≤150 | ≤250 |

3 | Steam pressure(MP) | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 1.8-2.0 |

Technical indicators of steam consumption for production equipment

Due to changes in production products and output, the gas consumption of various production equipment also has certain changes.

Steam generation process

Equipment for steam generation process

The most important equipment for the steam generation process is the steam boiler.

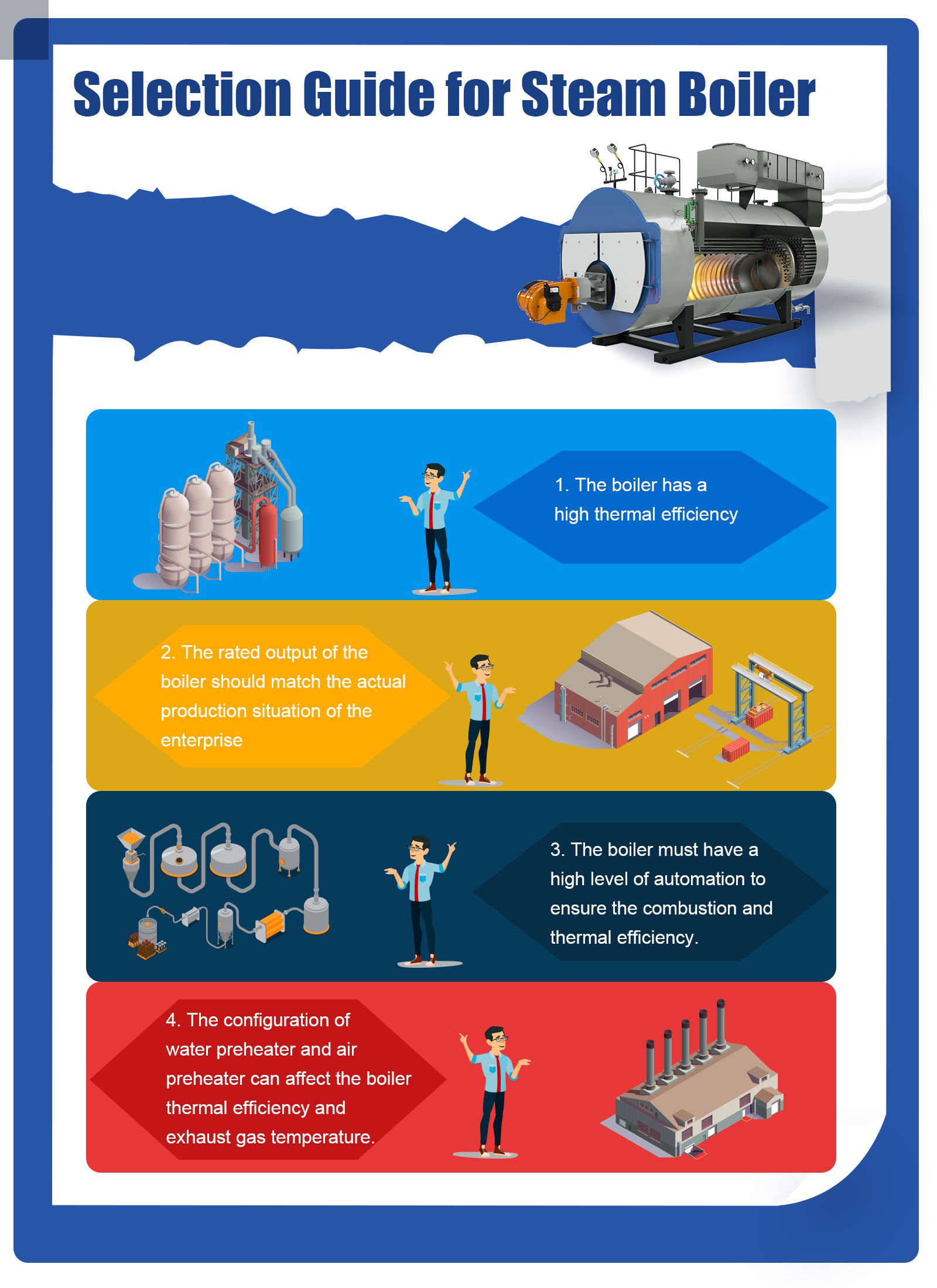

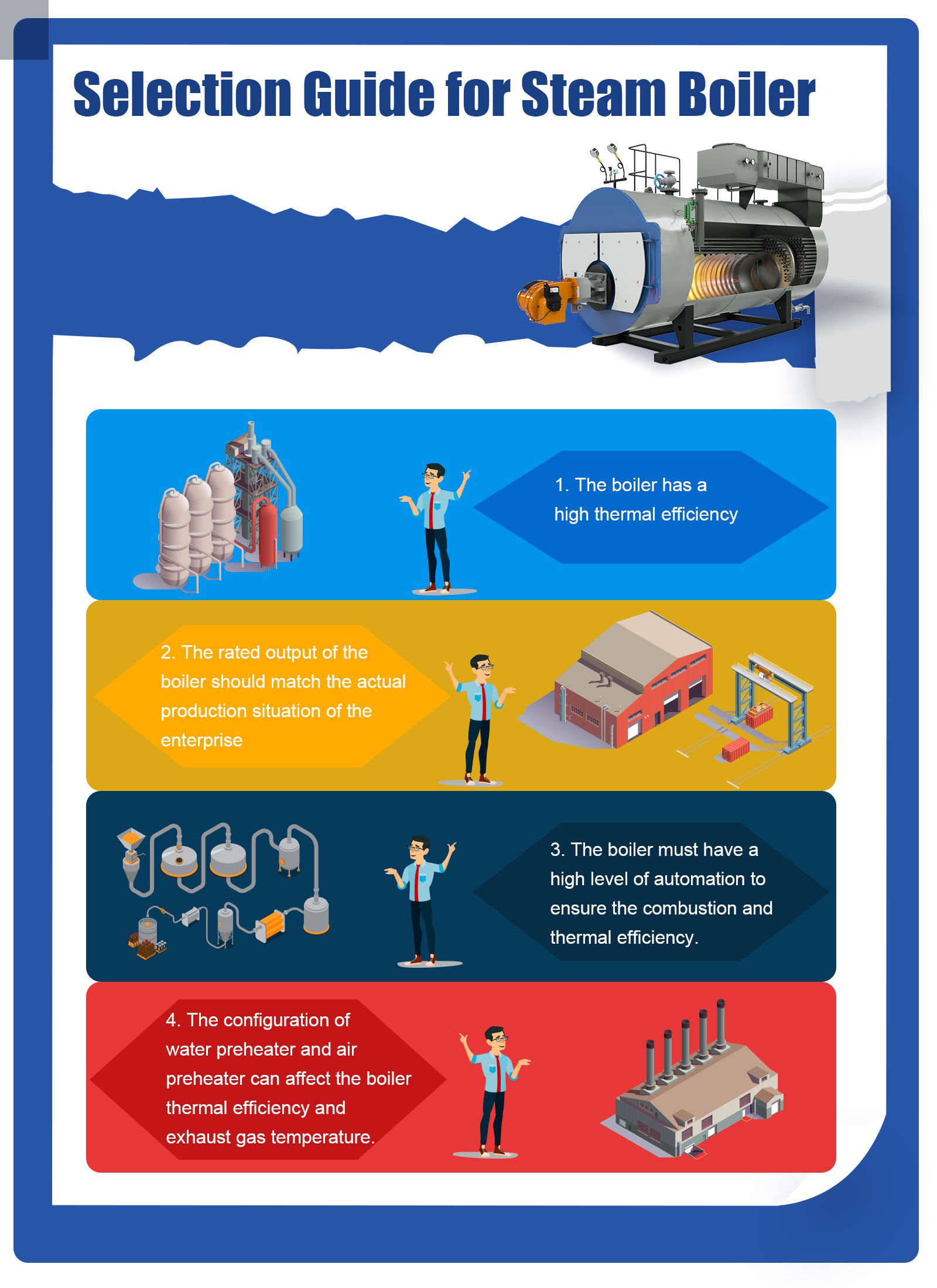

The selection of steam boiler should consider the following aspects:

1. The boiler thermal efficiency: the model or type with higher thermal efficiency should be selected.

2. The boiler Rated output: determine the required amount of steam according to the production situation of the enterprise, and then determine the rated output of steam boiler. To obtain higher thermal efficiency, the actual production demand should be within the scope of the stable operation of the boiler.

3. Boiler automation level: the higher the boiler automation level, the more guaranteed the complete combustion and higher thermal efficiency. For example, with a high degree of automation, the ratio of gas to air can be adjusted at any time, and the excess air factor can be strictly controlled to ensure higher thermal efficiency.

4. Water preheater and air preheater: the quality and performance of water preheater and air preheater also affect boiler thermal efficiency and the exhaust gas temperature. The heating area of the water preheater and the air preheater is large, the thermal conductivity of the material is good, and the effect of using the waste heat of the flue gas is high, so that the inlet water temperature and the inlet air temperature are higher, and the heat energy utilization efficiency is improved.

Serial Number | Technical Index | Unit | Gas-fired Boiler | Coal-fired Boiler |

1 | Thermal efficiency | % | ≥95 | 80-85 |

2 | Flue gas discharge temperature | ℃ | ≤88 | ≥120 |

3 | Air excess coefficient |

| 1.1-1.4 | ≥2.0 |

Some technical indicators of gas-fired boilers and coal-fired boilers

It can be seen from the table that the main technical indicators of gas-fired boilers are better than coal-fired boilers.

Management of steam generation process

The key points of the management of the steam generation process are:

1. Uniform steam supply: uniform steam supply can reduce the fluctuation of steam pressure and temperature, and can also reduce the rapid changes in combustion conditions. The point of uniform steam supply lies in the uniform supply of steam every day. If the order fluctuates greatly, production should be arranged reasonably.

2. Equipment maintenance: Compared with coal-steam boilers, the maintenance intensity of gas-fired steam boilers is greatly reduced. However, combustion is a high temperature and strong oxidation process, and the maintenance and maintenance of various equipment is still very important. For example, if the water preheater and air preheater are not maintained in time, the heat exchange efficiency will be reduced, and finally the thermal efficiency of the boiler will be affected.

Steam Delivery Process

The equipment in the steam transportation process mainly includes steam pipes, valves, sub-cylinders, and temperature and pressure reducers.

steam pipes

The selection, installation and insulation of steam pipes play a very important role in reducing heat loss.

Steam pipe diameter selection : Choosing an appropriate steam pipe diameter can reduce the pressure of the transportation process, thereby reducing the heat loss of the steam during the transportation process. In delivering the same amount of steam, when the pipe diameter is 50mm, 3.5BAR pressure is required, and when the pipe diameter is 65mm, only 1.5BAR is needed.

Steam pipes Installation: During the installation of steam pipes, pay attention to the angle of turning, and at the same time, pay attention to the connection method of the main steam pipe and each branch pipe.

Steam pipes Insulation: good insulation of steam pipes is an important way to reduce heat loss. There is a larger surface area in the entire steam pipe, which will result in a larger heat loss. Some steam pipes are in the open air or humid environment, and heat preservation is even more important.

Specification | DN50 | DN80 | DN100 | DN125 | DN150 | DN200 | DN250 |

Pipe diameter(mm) | 57 | 89 | 108 | 133 | 159 | 219 | 273 |

100m surface area(M2) | 17.9 | 27.9 | 33.9 | 41.8 | 49.9 | 68.8 | 85.7 |

Part of the surface area of 100 meters of steam pipes

The boiler heat dissipation area is about 130m2. The distance from the boiler room to the machine platform is several hundred meters. so the steam pipes heat dissipation area is almost similar to the boiler heat dissipation area.

The steam pipes heat preservation mainly do the following work:

1. Choose heat insulation materials that are good for heat insulation;

2. Properly control the thickness of the insulation layer;

3. Use non-absorbent materials as the protective layer of the insulation layer, especially in the open air and humid environment.

Regulation of steam delivery

In order to prevent instantaneous increase or decrease of steam consumption, in addition to reasonable arrangements for production, it is also necessary to ensure on the equipment, especially the steam required for dyeing, which often rapidly increases or decreases the amount of steam. For this reason, a heat storage tank is added to the steam supply system, which can alleviate the rapid increase or decrease of steam and achieve stable steam supply.

Management of the steam delivery process

The management of the steam delivery process focuses on regular inspection and maintenance of the insulation layer. Under normal circumstances, the loss of steam in the transportation process may exceed 15%. After using the gas boiler, by strengthening heat preservation and heat preservation maintenance, the steam transmission loss is reduced by 4-5%.

Steam Usage Process

Steam-consuming equipment

To reduce steam consumption, it is necessary to improve the thermal efficiency of steam-consuming equipment and select production equipment with higher thermal efficiency. After the use of gas boilers, it is one of the indispensable tasks to introduce dyeing machines with the lowest heat consumption and reduce production heat energy.

NO. | Item | Old model dyeing machine | New dyeing machine | Comparison of results |

1 | Dyeing bath ratio | 1:6-7 | 1:4.5-5 | reduced by 30% |

2 | Light and medium color dyeing steam consumption | about 2.5 tons | about 2 tons | reduced by 20% |

3 | Steam consumption for dark dyeing | about 4 tons | about 2.8 tons | reduced by 30% |

Comparison of steam consumption of two dyeing machines

It can be seen that by using a new type of dyeing machine, steam consumption can be reduced by 20-30%.

Improvement of production process

The traditional dyeing production process of knitted fabric is dip dyeing. The production process of dip dyeing is that the pretreatment, dyeing and softening treatment are all carried out in the same dyeing machine, which belongs to batch production and high energy consumption. In order to further reduce the energy consumption of production, the flat-spoke continuous scouring and bleaching production equipment and process and the pre-treatment process of the cold pile method are introduced, and then according to the production volume and product types, the production process of multi-process combination is realized, and the steam required for production is reduced.

It can be seen from the figure that, in the production process, the addition of a production process with low energy consumption for cold pile pretreatment and flat-width washing can reduce the heat energy consumption of production. Actual production data statistics can reduce heat energy consumption by about 30%.

Waste heat recovery and utilization

In order to improve the efficiency of heat energy utilization, three waste heat recovery and utilization systems have been established after the use of gas boilers.

1. Boiler flue gas waste heat recovery and utilization system

The roll guard flue gas waste heat recovery system is composed of a water preheater and an air preheater, and is installed in a gas boiler. The water heat exchanger uses air to preheat the incoming water. After heating, the inlet water temperature can reach 104°C. The air preheater is used to heat the inlet air temperature. The air temperature can be reached by the air preheater to reduce gas consumption.

2. Steam waste heat recovery system of setting machine

In the production process, the heat source of the setting machine is steam. Since the setting temperature of the setting machine is 120-200℃, part of the steam after the fixed work is condensed into water, and part is still steam, forming a steam-water mixture. After the steam-water mixture enters the flash tank, lower-pressure steam can be generated, which can be reused as the steam required by the dyeing machine. The steam-water mixture and the hot water generated in the flash tank are used as hot water for the dyeing machine. The steam waste heat recovery system of the shaping machine is also a multi-stage steam utilization system, which improves the efficiency of steam utilization.

3. Condensate waste heat recovery system

Condensed water will be generated when steam is heated by equipment such as dyeing machine, setting machine and dryer. Condensed water has better water quality and high water temperature (generally 70-85°C). After the condensate is collected, it can be reused as boiler water.

Benefit Analysis

1. Energy-saving benefit analysis

Thermal efficiency analysis of steam system

As mentioned earlier, when using gas boilers, the entire steam system needs to be improved to improve heat utilization efficiency. The thermal efficiency comparison of gas boiler system and coal boiler system can be seen in Table .

NO. | Item | Coal-fired boiler steam system | Gas-fired boiler steam system | Energy saving effect |

1 | Fuel storage loss | 2.5-3% | 0 | Reduce fuel loss by 1.5-2% |

2 | Boiler thermal efficiency | 80-86% | ≥95% | Improve thermal efficiency by more than 10% |

3 | Steam transmission loss | 12-15% | 8-9% | Reduce heat energy loss 4 |

4 | Produce steam consumption | 3.5t/t | 2.54 | Reduce consumption by 28% |

5 | Steam waste heat recovery of the shaping machine | 60% | =94% | Improve waste heat recovery efficiency by more than |

6 | Steam condensate recovery | ≤60% | ≥80% | Improve heat utilization efficiency by 20% |

Comparison of thermal efficiency of two steam systems

It can be seen that by improving and strengthening the management of the entire boiler system, the thermal energy utilization efficiency of the gas boiler steam system has been greatly improved.

Heat consumption per unit product

The benefit of energy saving can also be indicated by the change in heat consumption per unit product. After using the gas boiler, the unit product heat consumption dropped from 1120kgce/t to 848kgce/t, a decrease of 24.3%. This is a comprehensive result of various energy-saving measures.

Environmental Benefit Analysis

The environmental benefits of using gas-fired boilers are also very obvious, reducing the amount of sulfur dioxide produced by 520 tons/year, reducing the amount of dust produced by 1850 tons/year, and reducing the production of nitrogen oxides by 36 tons/year. It can be seen that the environmental benefits are very significant.

Analysis of economic benefits

Because the price of natural gas is much higher than that of coal. Although a lot of energy-saving work has been done, it is unrealistic to completely offset the impact of gas prices. However, the use of gas boilers still reduces costs in terms of personnel costs, pollutant treatment costs, and pollution discharge costs.

NO. | Project | Coal-fired steam system | Gas-fired steam system | Economic benefits |

1 | Labor cost | 12 people*50,000/year=600,000/year | 2 people*50,000/year=100,000/year | 500,000/year |

2 | Desulfurization cost | 352,000/year | 0 | 352,000/year |

3 | Denitration costs | 348,000 yuan | 0 | 348,000 yuan |

4 | Total |

|

| 1.2 million/year |

It can be seen that the use of gas boilers still has certain economic benefits.

Conclusion

1.The use of gas-fired boilers requires new design concepts, and some practices in coal boilers need to be changed.

2. The establishment of a gas boiler steam system requires comprehensive consideration and overall planning, including steam pressure, steam temperature, steam delivery routes, and various steam-consuming equipment.

3. When using gas boilers to replace coal boilers, carry out a series of energy-saving work centering on reducing production and energy costs, and strive to achieve the best economic benefits.

4. With the increasing pressure on environmental protection, the economic and environmental benefits of using gas-fired boilers will become more and more significant.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler