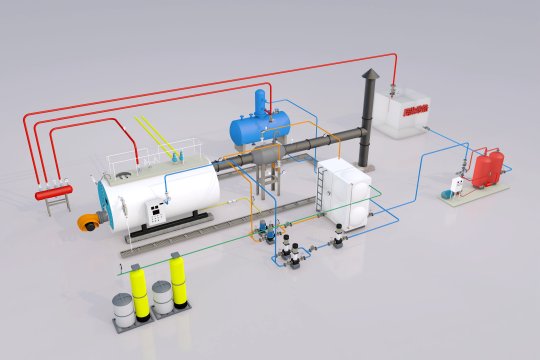

In industrial production, steam boiler is an indispensable equipment, which provides the necessary thermal energy support for the technological process. Whenchoosing industrial boilers, efficiency becomes a key consideration, because it is not only related to the production efficiency of enterprises, but also directly affects the long-term operating costs. An efficient boiler can perform well in fuel conversion and energy utilization, avoid unnecessary energy waste, and bring sustainable economic benefits and competitiveness to enterprises.

In the operating cost of industrial boilers, fuel costs account for a considerable proportion, which is usually much higher than the initial installation cost of equipment. The fuel saving brought by an efficient boiler may offset the installation cost of equipment within the first year, bringing considerable economic returns to enterprises.

Therefore, the selection of efficient industrial boilers will not only help to reduce production costs, but also enhance the dominant position of enterprises in energy management.

Understanding Boiler Efficiency: Key Terms and Definitions

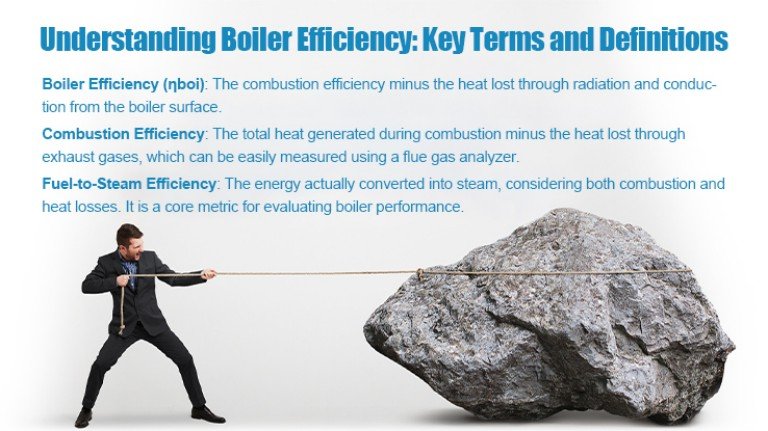

Boiler efficiency is a key index to measure boiler performance and energy utilization level, which is very important to reduce operating costs and emissions. However, boiler efficiency involves many professional terms and definitions, such as thermal efficiency, combustion efficiency, smoke loss, etc. Understanding them can help you quickly grasp the core concepts of boiler efficiency and provide scientific basis for boiler selection and energy efficiency optimization.

Boiler efficiency (ηboi)

Boiler efficiency is a measure of the ability of boiler system to convert fuel into useful heat energy. Specifically, it refers to the effective heat utilization rate after the total heat generated by combustion is subtracted from the heat lost by radiation and heat conduction on the boiler surface. Simply put, boiler efficiency can be expressed as the ratio of the actual thermal energy output by the boiler to the thermal energy of the fuel used, which is a key index to measure the energy utilization efficiency of the boiler.

Combustion efficiency and fuel-steam efficiency

Combustion efficiency

Combustion efficiency reflects the total heat generated by fuel in the combustion process, MINUS the heat in the exhaust gas. This index measures the degree of fuel combustion and burner performance, and can be measured by combustion gas analyzer. Generally, the improvement of combustion efficiency means that more fuel energy is fully converted into heat, while the loss of unburned fuel and exhaust gas is reduced. This measurement method enables the boiler operation process to be better controlled and optimized.

Fuel-steam efficiency

Fuel-steam efficiency not only considers combustion efficiency, but also comprehensively considers the actual situation of heat loss and heat conversion. In short, this index measures the actual energy ratio of fuel to steam in boiler system. Compared with simple combustion efficiency, fuel-steam efficiency provides a more comprehensive evaluation of the overall performance of the boiler, because it reflects the energy loss in the whole process from fuel combustion to steam generation. Therefore, the fuel-steam efficiency has important reference value in boiler selection and performance optimization, and provides an important direction for maximizing heat energy conversion and economic benefits.

Factors Affecting Boiler Efficiency

Improving boiler efficiency can not only maximize fuel utilization, but also reduce emissions and save costs. However, there are many factors that affect the efficiency of the boiler, including heat loss management, waste gas emission control, air/fuel ratio adjustment and changes in load conditions. Understanding these factors deeply and taking corresponding optimization measures will help enterprises to improve production efficiency and realize more environmentally friendly and economical energy utilization.

Heat loss in the boiler system

The heat loss of boiler system is mainly caused by radiation and heat conduction. Even under the best operating conditions, some heat will be dissipated from the boiler surface to the surrounding environment in the form of radiation or conduction. This heat loss will be significantly different under different load conditions and downtime.

Insulation thickness: the thickness of insulation material outside the boiler plays an important role in heat retention. Good insulation can significantly reduce heat loss and improve overall efficiency. Too thin insulation layer may lead to a lot of heat energy dissipation, increasing fuel consumption and operating costs.

Operating pressure: The operating pressure of the boiler will affect the heat retention. Usually, higher operating pressure will lead to an increase in temperature difference, thus increasing heat loss. Therefore, it is critical to balance pressure level and heat retention in operation and design.

Waste gas loss

Waste gas loss is a major source of boiler heat loss. The high-temperature exhaust gas after combustion will carry a lot of heat energy. If it is not fully utilized or recovered, this part of energy will be lost with the smoke exhaust. A lower exhaust gas temperature usually indicates that the system operates more efficiently because more heat energy is transferred to the process steam or hot water. However, reducing the exhaust gas temperature is not always beneficial-when the exhaust gas temperature is too low, it may lead to condensation, which may lead to corrosion problems and damage the long-term stability of the boiler. Therefore, optimizing exhaust gas temperature needs to find a balance between improving efficiency and avoiding condensation.

Control of air/fuel ratio

Proper air/fuel ratio is the key to ensure complete fuel combustion. Excess air helps to provide enough oxygen for complete combustion, thus improving combustion efficiency and reducing unburned fuel emissions. However, too much excess air will reduce the combustion temperature and cause the exhaust gas to carry more heat out, resulting in heat loss. Therefore, in actual operation, it is very important to accurately control the air/fuel ratio, which usually depends on modern control system and burner technology to achieve optimization and adjustment.

Load conditions

The efficiency of boiler operation under different load conditions will be different. When the boiler runs at full load (100%), its efficiency is usually the highest, because the utilization rate of heat and energy is relatively high. As the load is reduced to 75%, 50% or even 25%, the boiler efficiency may gradually decrease. This is because under the condition of partial load, the combustion process and heat distribution of the boiler are often difficult to reach the best state, and some energy will be lost in the conversion process.

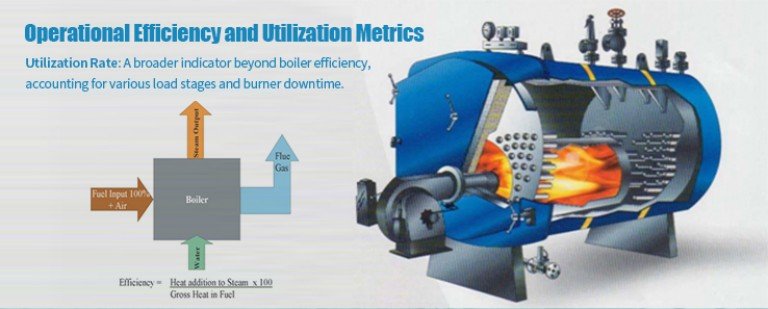

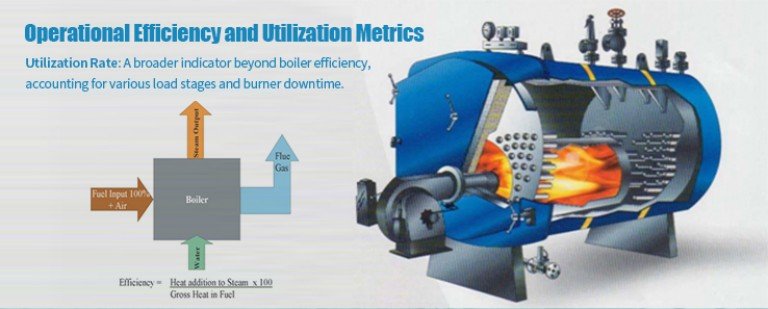

Operational Efficiency and Utilization Metrics

Overview of utilization rate

When evaluating boiler performance, in addition to boiler efficiency, utilization rate is also a key comprehensive index. The utilization ratio measures the actual performance of the boiler in various load stages and burner shutdown time. It not only pays attention to the fuel-steam conversion efficiency, but also reflects the overall performance of the boiler under different operating conditions and the effectiveness of the service time. A boiler with high utilization ratio usually shows that it can run efficiently in actual operation, reducing downtime and improving the conversion efficiency of total energy consumption.

Load management and operation scheduling

Load management and proper operation scheduling are very important for reducing heat loss and improving the overall efficiency of boilers. Reasonable load distribution can ensure the boiler to operate in an optimal state and avoid energy waste and extra fuel consumption caused by unstable load. When the demand fluctuates greatly, optimizing the boiler operation scheduling can reduce the energy loss and radiation loss caused by frequent start-stop For example, in the period of low demand, the boiler can be kept running stably by reasonably arranging and distributing the load, thus reducing the heat loss and improving the utilization rate.

Advances in Boiler Technology and Control Systems

Progress in modern burner design

Innovation of modular water tube boiler: EPCB modular water tube boiler has remarkable quick start performance, which is different from the traditional large boiler system, and its design can run from cold start to full load in a short time. This feature is very important in industrial applications, because it can effectively reduce energy consumption during long standby.

In addition, the modular design of EPCB modular water tube boiler can be flexibly combined and expanded to meet the demand changes of different factories for production capacity. Another important advantage of modular system is that it can adjust the load according to the change of demand, thus further reducing unnecessary energy consumption and heat loss. This flexibility not only optimizes the operation efficiency, but also significantly reduces the consumption of standby fuel.

Adjustment ratio of advanced burner: Advanced burner design usually has a high adjustment ratio, which can accurately adjust the boiler output according to the load demand. Traditional burners can only operate at a fixed power, while modern burners can be adjusted efficiently in the output range as low as 10% to as high as 100%. This flexibility ensures that the boiler can operate efficiently under partial load, reducing fuel waste and operating costs. At the same time, this flexibility helps to reduce the wear and tear caused by frequent start-up and stop, and prolong the service life of the equipment.

Closed loop control system

Accurate air/fuel ratio management: Modern boilers are usually equipped with a closed-loop control system to monitor the oxygen content in the combustion process through precision equipment such as oxygen sensors. Based on real-time oxygen concentration feedback, the system can automatically adjust the mixing ratio of air and fuel to ensure the best combustion efficiency. Such air/fuel ratio management not only significantly improves the combustion efficiency of the boiler, but also effectively reduces harmful emissions, such as NOx and CO.

Maximize efficiency and reduce emissions: The application of closed-loop control system helps modern boilers to achieve more accurate combustion control, so that they can always maintain a high level of energy efficiency under different loads and working conditions. By reducing the incomplete combustion of fuel and the introduction of excessive air, the emission level of the boiler is greatly reduced, thus better meeting the strict environmental regulations. This technological progress is not only beneficial to environmental protection, but also provides an important guarantee for enterprises to save costs and improve productivity.

Environmental Considerations: Low NOx Emissions

In the design and operation of industrial boilers, improving efficiency and reducing nitrogen oxide (NOx) emissions are key considerations to achieve sustainable development goals and comply with environmental regulations. NOx is one of the main pollutants that cause air pollution and acid rain, and reducing its emissions is very important to slow down climate change and improve air quality. Modern boiler design and technological innovation, especially the application of low NOx technology, provide enterprises with efficient and environmentally friendly solutions.

Relationship between improving efficiency and reducing NOx emission

The combustion efficiency of boiler is closely related to NOx emission. Low combustion efficiency will lead to incomplete fuel combustion and generate excessive harmful gases; However, efficient combustion can ensure the full combustion of fuel and reduce the generation of nitrogen oxides by optimizing the ratio of air to fuel and accurately controlling the combustion temperature. In addition, the generation of NOx is also directly related to the combustion temperature. By adopting staged combustion, low temperature combustion and air classification technology, the boiler can reduce the combustion temperature and NOx production at the same time, thus achieving the dual goals of environmental protection and energy saving.

Boiler design supporting environmental protection operation

Modern boilers are generally equipped with low NOx burners to reduce NOx emissions by staged combustion and controlling the mixing of air and fuel. These burners have high precision control ability, can be dynamically adjusted to adapt to load changes, and maintain efficient and stable heat output at low temperature. In addition, the exhaust gas recirculation (FGR) technology reduces the oxygen concentration and combustion temperature in the combustion chamber by introducing part of exhaust gas, thus reducing the amount of NOx generated, and is integrated into the advanced control system to ensure safety and stability. At the same time, the use of environmentally friendly materials and coatings with high temperature resistance and corrosion resistance is also helpful to reduce pollutants caused by wear and incomplete combustion.

Comply with environmental regulations and support sustainable development goals.

With the improvement of environmental protection requirements, various laws and regulations set strict limits on NOx emission. By adopting advanced technologies such as low NOx burners and waste gas recycling, enterprises can not only meet the requirements of laws and regulations, but also enhance their environmental image and market competitiveness. The application of these environmental protection designs and technologies supports enterprises to reduce their carbon footprint, achieve sustainable development goals, and reduce the impact on the environment.

Conclusion

The selection and maintenance of efficient industrial boilers need to pay attention to the fuel-steam conversion efficiency of boilers. Efficient boilers can not only optimize energy consumption, but also maintain excellent heat insulation performance, load adaptability and flexible control system during use, thus ensuring stable and efficient operation of equipment under different working conditions. This comprehensive consideration is helpful to improve the overall performance of boilers and bring sustainable benefits to enterprise production.

By selecting high-efficiency boilers, enterprises can maximize fuel savings and reduce operating costs, while actively responding to environmental protection goals and reducing emissions. With the rising energy costs, the long-term use of high-efficiency boilers can significantly reduce the overall expenditure, achieve significant cost-effectiveness and better environmental performance, and promote the long-term development of enterprises in green production.

If you need to improve boiler efficiency and find customized solutions, please contact EPCB boiler. Our professional team will provide you with comprehensive consultation and guidance to help you achieve a more efficient and environmentally friendly energy use plan.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler