Introduction

The use of biomass boilers as a sustainable energy source is gradually increasing, mainly driven by its advantages in terms of environmental friendliness, renewability, and regional accessibility. Biomass boilers utilize biomass as a fuel, such as wood chips, straw, discarded crops, wood waste, etc., which is burned to produce heat for heating, power generation, or industrial production purposes.

However, biomass boilers face some potential problems during operation, which are important for optimizing boiler performance. For example, uneven fuel quality can affect the stable operation and performance of the boiler. Ash from biomass combustion contains high concentrations of alkali and heavy metals, and the chemical composition in the fuel leads to corrosion of boiler piping, affecting thermal efficiency and equipment life. As a senior boiler production and manufacturing supplier, EPCB Boiler will summarize the common problems of biomass boilers and will help to promote the wide application and sustainable development of biomass boilers by solving the problems of raw material supply, environmental pollution, economics and policy and regulatory restrictions to improve the efficiency and environmental protection performance of biomass boilers, to reduce the cost and to increase the competitiveness of market, which will help to promote the wide application of biomass boilers and the sustainable development of biomass boilers.

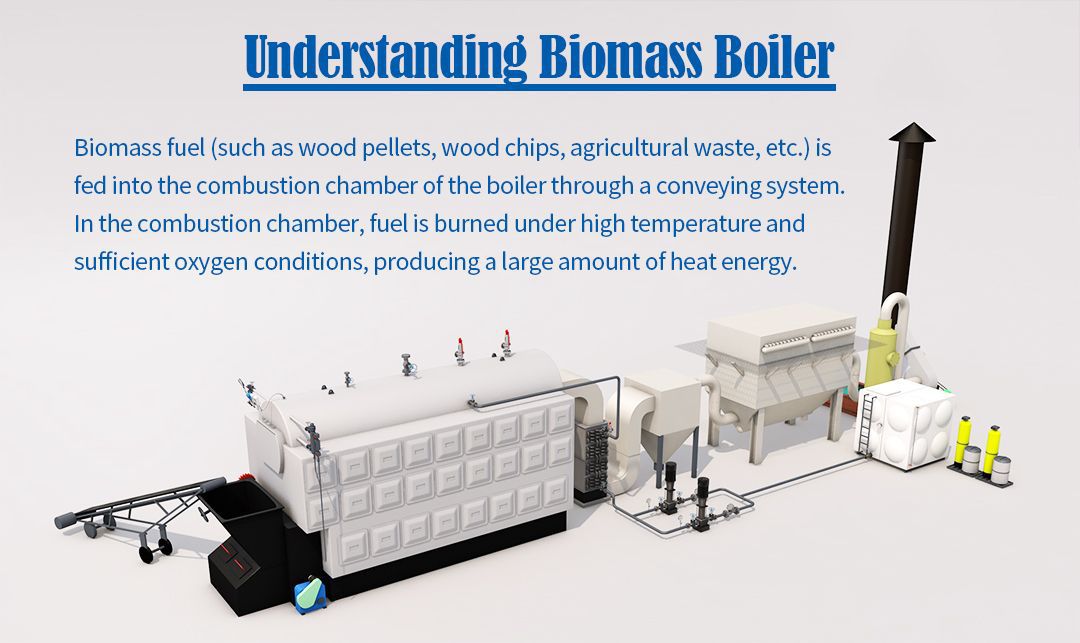

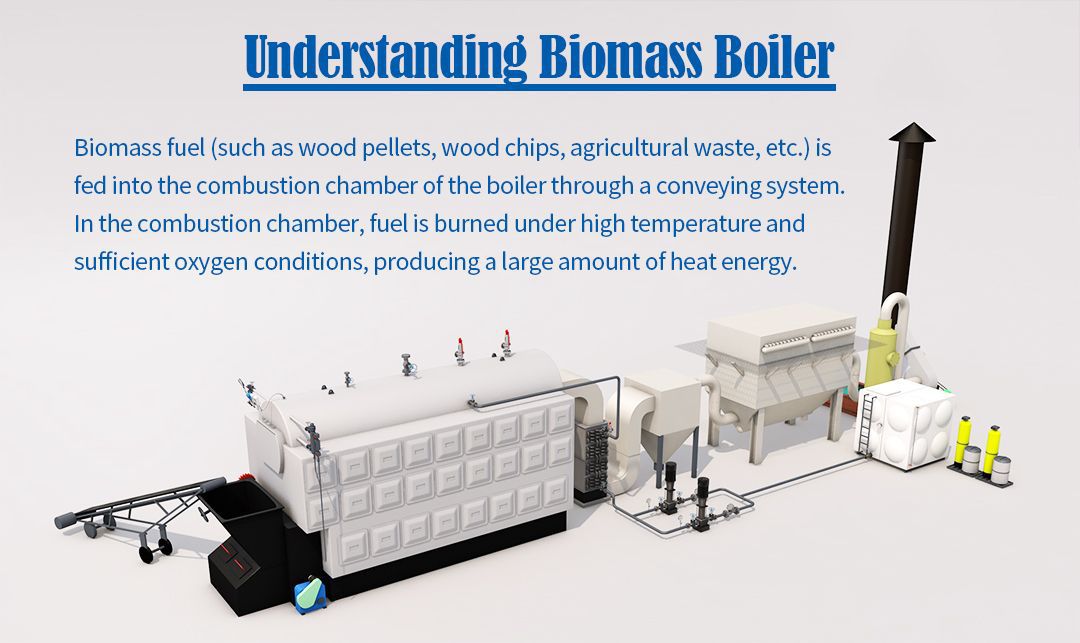

Understanding Biomass Boiler

A biomass boiler is a type of boiler that uses biomass as its main fuel, which can effectively utilize renewable energy to generate clean energy.

The working principle of a biomass boiler is relatively simple and intuitive. Biomass fuels (e.g. wood pellets, wood chips, agricultural waste, etc.) are fed into the combustion chamber of the boiler through a conveyor system. Inside the combustion chamber, the fuel is burned at high temperatures and with sufficient oxygen to produce a large amount of heat energy. This heat energy is transferred to water or other heat transfer medium through the heating surface of the boiler, heating it to a high-temperature steam or hot water state.

Biomass boilers use a wide range of fuel types, mainly including wood pellets, wood chips, and agricultural wastes. These biomass fuels are rich in sources and can be recycled, and the carbon dioxide produced during the combustion process can be absorbed by plants, forming a carbon cycle and reducing greenhouse gas emissions. In addition to this, there are advanced biomass boilers that can be fueled with more challenging materials, such as vegetable oils and animal fats.

Common operational issues with biomass boilers

Biomass boilers have gained popularity as a renewable and sustainable alternative to traditional fossil fuel boilers. However, like any other technology, they face their own set of operational challenges.

One of the most important issues facing users of biomass boilers relates to the quality of the fuel used. Biomass fuels such as wood chips, sawdust, or pellets vary in size and moisture content, which can significantly affect the combustion process and lead to inefficient combustion or even complete system shutdown. It is, therefore, crucial to choose a reliable supplier, and EPCB Boiler can provide consistently sized and dry biomass fuels, which not only ensures optimal combustion but also extends the life of the boiler.

Another key aspect that affects the operation of a biomass boiler is fuel handling. Due to their lower energy density compared to fossil fuels, biomass boilers require large quantities of biomass fuel for their applications. Proper storage, transportation, and feeding systems are essential for smooth operation. Therefore, it is recommended to perform regular maintenance checks and ensure that fuel-handling equipment meets industry standards.

Additionally, ash buildup within a biomass boiler can negatively impact its overall efficiency by obstructing heat transfer surfaces and preventing airflow through the furnace. To prevent this problem from occurring too frequently, regular cleaning must be carried out using appropriate techniques, and proper management measures should also be taken when disposing of the ash, which contains a large amount of unburned carbon and can be hazardous to the environment if not handled correctly.

Mechanical issues and maintenance challenges

As biomass boilers become more widely used, their mechanical issues and maintenance challenges are surfacing as key factors that affect the stable operation and long-term benefits of biomass boilers.

One of the key issues facing biomass boiler owners is component wear and tear. Constant exposure to high heat levels can lead to premature deterioration of critical components, affecting the overall performance and efficiency of the boiler. That's why regular inspections and timely replacement of worn parts are critical to ensuring the longevity of your boiler.

Another issue that plagues biomass boilers is corrosion and erosion. The acidic nature of some types of fuel used in these boilers can cause corrosion of metal surfaces, leading to leaks and breakdowns. Proper fuel selection and handling can help alleviate this problem, but regular monitoring is still needed to catch any signs early.

In addition to physical wear and tear, another major challenge in biomass boiler maintenance relates to automated control systems. These complex systems rely heavily on sensors and control mechanisms that can easily malfunction or fail over time. Clogging due to ash buildup in pipes or filters, faulty wiring connections, and even software malfunctions are all factors that can lead to potential failures that require immediate attention.

Efficiency and Performance Degradation

Efficiency and performance degradation can be a major problem for any industrial boiler operator. Not only does it affect the overall functionality of the equipment, but it can also lead to higher energy costs and potential safety hazards. To understand the root cause of this problem, we must first examine the various factors that can lead to fluctuations in efficiency and performance.

One of the main reasons for inconsistent boiler efficiency is changes in load demand. It is well known that boilers are designed to meet a specific heat output based on their maximum capacity. Any fluctuation in demand leads to changes in the rate of combustion, which ultimately affects the efficiency level.

Another important factor that leads to a drop in efficiency is inefficient combustion. This happens when there is an insufficient supply of oxygen during combustion, resulting in incomplete combustion of biomass fuel. This not only wastes valuable resources but also produces harmful emissions such as carbon monoxide, which pose a threat to human health and the environment.

In addition, boilers are susceptible to reduced heat transfer due to the accumulation of scale on the surface of the heat exchanger. The accumulation of mineral deposits, such as scale, significantly affects the rate of heat transfer, and these deposits act as insulators, preventing effective heat exchange between hot gases and water, and leading to reduced efficiency levels over time.

To address these issues and improve boiler performance, regular maintenance checks should be carried out by a qualified professional specializing in industrial heating systems. By understanding the various factors that contribute to reduced efficiency, implementing appropriate controls, and investing in a regular maintenance program, we can ensure optimal boiler operation and ultimately improve the profitability of our business.

Environmental and Regulatory Challenges

Environmental and regulatory challenges are major issues in today's global landscape. As industries continue to grow and expand, the impact on the environment cannot be ignored. To meet these challenges, companies using biomass boilers must not only comply with local environmental regulations but also proactively address issues such as emissions control, noise pollution, and dust management.

In terms of environmental impact, one of the most pressing issues is emissions. As industrialization increases, so do greenhouse gas emissions, which have a significant impact on climate change. To address this issue, companies must strictly comply with local laws and regulations regarding air quality standards. This means regularly monitoring their emission levels and taking effective measures, such as installing emission control systems or using clean energy.

Another aspect that should not be overlooked when discussing environmental challenges is noise pollution and dust management. Manufacturing processes often generate waste such as chemicals or excess materials, which can contaminate soil and water if not handled properly. Noise and dust issues are especially important in industries that involve large machinery or construction activities. Excessive noise can not only cause discomfort to nearby communities but can also adversely affect wildlife habitats. Similarly, uncontrolled dust particles may cause respiratory problems for workers in the industry as well as for surrounding residents.

Solutions and Troubleshooting Tips

When it comes to solutions and troubleshooting tips, a high-quality fuel supply is a key factor in ensuring that your system operates properly. First and foremost, it is important to realize that fuel, as the heart of a biomass boiler, has a direct impact on the performance and efficiency of the entire system. Therefore, it is very important to adopt some tips to ensure a high-quality fuel supply.

Select a reliable and high-quality supplier to provide fuel. Conduct thorough research before selecting a supplier and reviewing their credentials and reputation. It is also a vital step to check that the product meets specifications before shipment.

Regular maintenance routines can also greatly extend component life and keep the entire system in good condition. Ensure optimal operating conditions by performing standard inspection activities, changing filters, and cleaning oil tanks.

Upgrading parts and systems where possible can also bring significant benefits. This not only improves performance levels but also makes the system more robust and increases its reliability. For example, in some cases, the use of durable materials or improved design can reduce costs, increase efficiency, and reduce maintenance time.

Solutions and troubleshooting tips are designed to ensure the highest levels of system performance and reliability. Be careful when choosing a fuel supplier and always keep in mind regular maintenance and upgrades to ensure you have a quality system that operates successfully!

The Role of Professional Services

The role of professional services is very important in all industries, especially when it comes to maintenance and repair. Whether you're an individual or a business, when problems arise, many people turn to experts to fix them.

So when should you hire a professional for maintenance and repair? Simply put, whenever it comes to the maintenance and repair of critical equipment or systems, it's best to leave it to the professionals. For example, a complex piece of equipment like a biomass boiler system needs to be meticulously maintained to function properly. If left in the hands of a non-professional, potential problems may be overlooked and the appropriate technical knowledge and experience may be lacking to solve the actual problem.

In addition, a thorough and accurate assessment needs to be carried out before any form of maintenance is carried out. This requires us to seek out and work with a reliable, qualified service provider with relevant experience as well as a good reputation. EPCB Boiler can identify the required maintenance and the potential problems that may exist through a thorough inspection and testing of the equipment, which will help us develop effective preventive measures.

Finally, choosing the right service provider is also crucial. For equipment as unique as a biomass boiler system, we need to look for companies that have the experience and credentials to provide a full range of services and have a good reputation, and EPCB Boiler will be able to not only provide us with routine maintenance and repairs but also customize a plan according to actual needs and provide technical support and solutions at any time.

Conclusion

Biomass boilers are facing multiple challenges in the current energy sector, including instability of biomass resource supply, environmental pollution problems during combustion, and high equipment and operating costs. To address these challenges, preventive measures and regular maintenance are essential. In addition, it is encouraged to seek the support of professional service providers who have the experience and advanced technology to provide comprehensive assessment and optimization to help resolve operational issues and further enhance the performance and efficiency of biomass boilers.

As a boiler provider with 70+ years of experience, EPCB Boiler's professionals have the expertise and skills needed to optimize boiler performance through advanced troubleshooting techniques and maintenance plans tailored to each facility's needs. If you have questions about operating your biomass boiler, feel free to ask EPCB Boiler

FAQ

What can I do if my biomass boiler is producing less heat than usual?

Biomass boilers are a very reliable and efficient heat transfer device. However, like any other piece of mechanical equipment, there may be certain issues that cause it to produce less heat than usual after prolonged use. The solution is as follows:

Step 1: Check the fuel supply

The check is whether the fuel supply it uses is adequate, and also the various pipes and filters should be cleaned regularly to prevent clogging from affecting the normal supply.

Step 2: Check airflow

Ensure that there are no blockages in the air conditioning system and implement effective cleaning measures to remove dirt, dust, or other contaminants.

Step 3: Adjust the Discharge Temperature

Try adjusting the discharge temperature and increasing the water circulation rate to increase the heat dissipation area.

Step 4: Inspect boiler piping

Inspecting and cleaning the various piping in your biomass boiler at certain intervals is also key to maintaining its efficient operation.

Step 5: Use high-quality fuel

Choosing high-quality, clean, unadulterated biomass as the primary fuel for your boiler will effectively minimize unnecessary fouling and damage to the discharge ports and other components.

How to prevent clogging in the fuel supply system?

In the industrial production and energy supply of biomass boilers, the stable operation of the fuel supply system is crucial. If the fuel supply system is clogged, it will not only affect the production efficiency but also may cause damage to the equipment and even lead to safety accidents. Therefore, we can take the following measures to prevent the fuel supply system from clogging.

Optimize the quality of fuel: choose dry biomass fuel with few impurities, and avoid using wood chips, straw, etc., which have too high water content or contain a lot of impurities.

Regular cleaning: Regularly clean the furnace, piping, and feeding system of the biomass boiler, remove the accumulated ash, burning residues, and clogging, and keep the system unobstructed.

Optimize the feeding system: Carry out a reasonable design of the feeding system to ensure that the fuel can be smoothly transported to the combustion chamber. At the same time, check the feeding system regularly to ensure that the silo and feeding pipes are free from blockage and failure.

Enhance equipment maintenance: Regularly maintain the biomass boiler's burner, feeder, and other key equipment to keep them in good working condition. This helps to reduce the clogging problem caused by equipment failure.

Reasonable control of the combustion process: By reasonably controlling the temperature of the combustion chamber, the supply of oxygen the amount of fuel input, and other parameters, to ensure that the biomass fuel can be fully combusted and reduce the ash and smoke produced by incomplete combustion.

Are there any signs of potential mechanical failure in the biomass boiler?

Early detection tips for boiler maintenance.

Perform regular cleaning and maintenance: just like a car needs regular maintenance, a biomass boiler needs regular cleaning and maintenance. Every 3-6 months, a major cleaning of the boiler should be done to remove the internal dirt such as dust and oil layers. Also To check whether the parts are functioning properly and replace the aging or damaged parts in time.

Pay attention to the air pressure and temperature changes: In biomass boilers in the working process, there will be fluctuations in air pressure and temperature, in the process of use should pay close attention to these parameters, and timely adjustments.

Check the water level and lubricating oil: water is the most important part of the biomass boiler, it plays a cooling role and helps to discharge the waste. If the water level is lower than the standard value, it will easily lead to biomass clogging and energy loss. In addition, with adequate lubrication oil, it can effectively reduce mechanical friction and prolong the life of parts.

All in all, please make sure to follow the operation manual strictly and seek professional maintenance regularly. If you find any abnormalities, please stop using it immediately and contact the manufacturer or relevant technicians for overhaul.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler