Overview

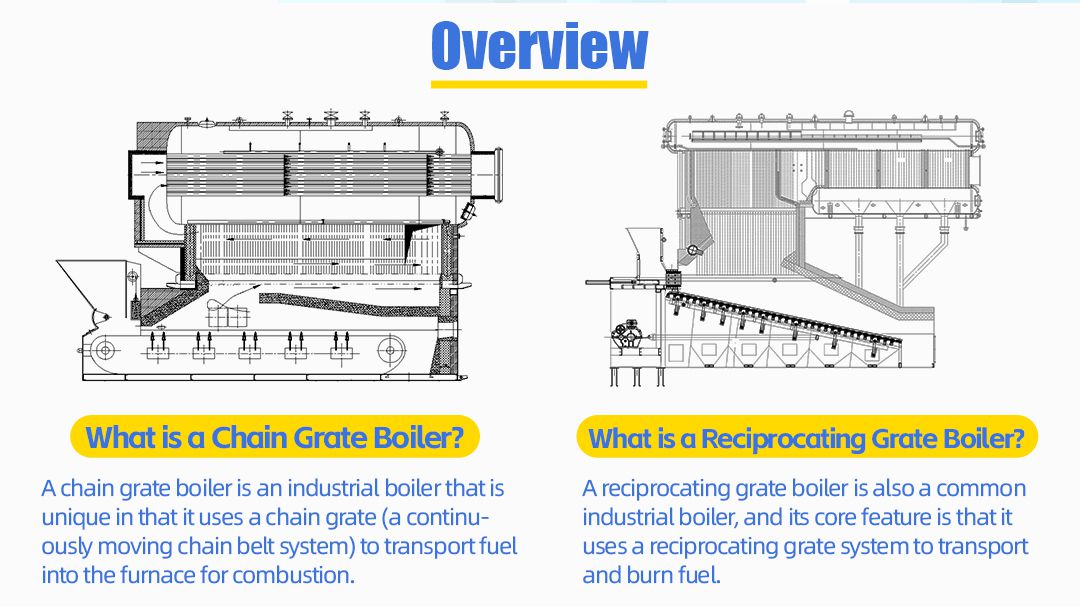

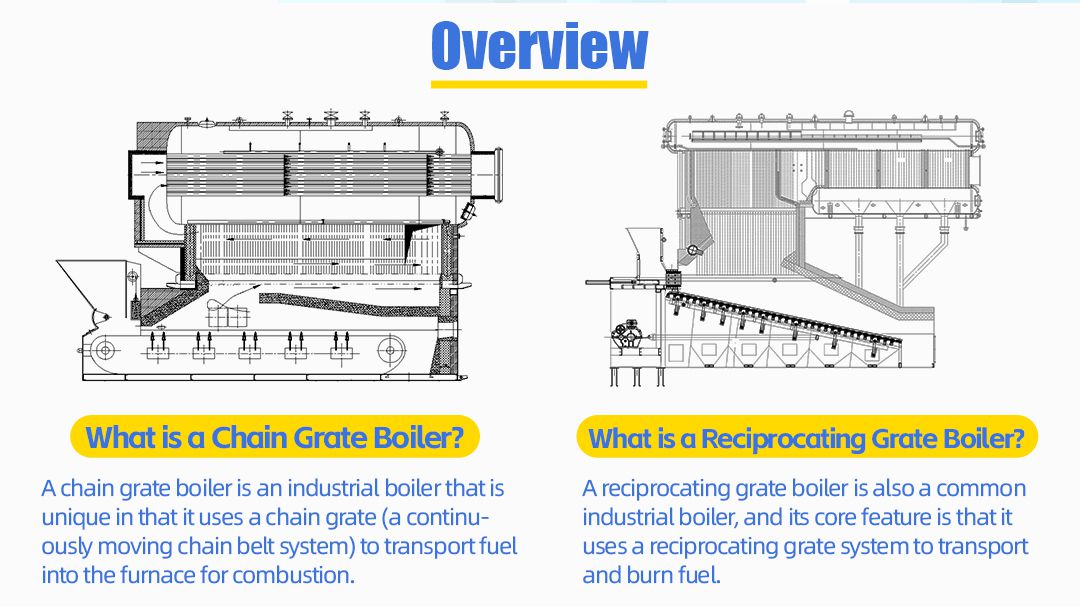

What is a chain grate boiler?

A chain grate boiler is an industrial boiler type. It is unique because it uses a chain grate to move fuel to the furnace for combustion. This design gives a steady supply of fuel. It also causes the fuel to burn uniformly on the grate. This improves combustion efficiency and heat use. Chain grate boilers are widely used in many industries. They were introduced in the early 20th century. They are popular because of their simple structure, easy operation, and adaptability.

What is a reciprocating grate boiler?

A reciprocating grate boiler is a common type of industrial boiler. Its core feature is the use of a reciprocating grate to convey and burn fuel. This design allows for even fuel distribution. It also allows for efficient combustion in the furnace chamber. This happens through the back-and-forth motion of the grate. Reciprocating grate boilers are good for burning many fuel types. They are used in industry due to their unique advantages in handling fuel and controlling combustion.

Next, EPCB Boiler will discuss how chain grate and reciprocating grate boilers work. They will compare their efficiency, fuel flexibility, environmental impact, cost, maintenance needs, and applications. This will help you understand the pros and cons of these boilers and make the best choice.

Working Principle

Working Principle of Chain Grate Boiler

Chain grate boilers convey fuel from the inlet to the furnace chamber through the operation of a continuous chain belt.EPCB boilers utilize an automatic feeding system to ensure the continuity and stability of the fuel supply. As the fuel advances, it dries, ignites, and burns, generating heat. The unburned residue is finally discharged at the end of the grate.EPCB chain grate boilers are equipped with an automatic slag discharge system, which reduces labor intensity and improves the continuity and stability of boiler operation.

Working Principle of Reciprocating Grate Boiler

Reciprocating grate boilers utilize a back-and-forth motion to agitate the fuel bed. This motion promotes uniform combustion by ensuring that unburned fuel is continually repositioned for optimal combustion. Reciprocating motion allows for better control of combustion air distribution, thus improving the efficiency and effectiveness of the combustion process.The EPCB Reciprocating Grate Boiler utilizes a precisely controlled reciprocating motion system that ensures uniformity and effectiveness of fuel agitation.

Efficiency Comparison

Combustion efficiency

Reciprocating grate boilers usually have an advantage in combustion efficiency. This is because of their dynamic fuel agitation. This results in more complete combustion and less unburned residue. Also, reciprocating grates are better for the type and shape of the fuel. They are especially good for fuels with high humidity. The drying and burning process can happen in stages. Chain grates, on the other hand, are better suited to combusting drier fuels, as wet fuels can lead to problems with grate sticking and incomplete combustion. As a result, reciprocating grate boilers are relatively more efficient in combustion.

Factors affecting efficiency

Boiler combustion efficiency is how well the boiler turns fuel's chemical energy into heat during combustion. High combustion efficiency means that more fuel energy is effectively utilized, and less energy is lost in the form of flue gas, ash, and so on. Many factors affect the efficiency of reciprocating grate boilers and chain grate boilers. These include fuel moisture, air distribution, and grate movement. Reciprocating grates have a mechanical design. They are often better at handling these variables, so they promote more complete fuel combustion.

Studies have shown that reciprocating grate boilers have combustion efficiencies up to 90%. This is higher than 85-87% for chain grate boilers. A reciprocating grate boiler is more efficient. It uses less fuel and emits fewer pollutants. This helps the overall performance of an industrial plant. Reciprocating grate boilers offer big advantages. They have low fuel use and operating costs due to their high combustion efficiency, which can reach 90%. Despite their high maintenance requirements, higher energy efficiency and economic benefits can be achieved by optimizing the fuel combustion process. Chain grate boilers are an important choice for many industries. They are easy to run and cheap to maintain. EPCB Boiler combines the advantages of the different grate types. They provide efficient and green industrial boiler solutions. These meet the needs of a wide range of customers.

Fuel Flexibility

Fuel types for chain grate boilers

Chain grate boilers are versatile but are best suited to solid fuels of uniform size such as coal, biomass pellets, and peat.

Chain grate boilers have a wide range of fuel suitability and are able to burn many types of solid fuels efficiently, including hard coal, lignite, anthracite, and biomass fuels (e.g., wood pellets, rice hulls, wood chips). Choosing the right type of fuel requires consideration of the calorific value, moisture and volatile content, ash content, and pollutant emissions of the fuel.EPCB Boiler combines the characteristics of different fuels to provide highly efficient, stable, and environmentally friendly chain grate boiler solutions to meet the needs of different industrial applications.

Fuel Types for Reciprocating Grate Boilers

Reciprocating grate boilers are more flexible and can efficiently burn a wider range of fuels, including wood chips, sawdust, agricultural waste, and even municipal solid waste.

Reciprocating grate boilers adapt to a wider range of fuel types including coal (hard coal, lignite, anthracite), biomass fuels (wood pellets, rice husks, wood chips), charcoal briquettes, municipal waste, and industrial waste due to their unique churning and combustion control mechanisms.EPCB Boiler combines the characteristics of different fuels to provide highly efficient, stable, and environmentally friendly reciprocating grate boiler solutions to meet the needs of different industrial applications.

Advantages and Limitations

Reciprocating Grate Boilers and Chain Grate Boilers each have advantages and limitations in terms of fuel flexibility. While chain grate boilers are simple and reliable, they are limited by fuel type and size, are less adaptable to specific fuels, and are more suited to handling large-capacity fuels and traditional solid fuels. Reciprocating grates, however, offer excellent fuel adaptability, with particular advantages in waste utilization, making them suitable for industries with diverse fuel supply chains. The selection of the right type of boiler should take into account industrial production requirements, fuel type and characteristics, and operating costs.

Environmental Impact

Emissions Comparison

Reciprocating grate boilers typically produce fewer emissions due to their higher combustion efficiency and better air control mechanisms. As a result, reciprocating grate boilers have lower levels of particulate matter emissions relative to chain grate boilers. Chain grate boilers, on the other hand, may have lower levels of NOx emissions. Both are relatively close in terms of CO2 emissions, depending on fuel type and combustion efficiency.

Ash and by-product management

Reciprocating grate boilers and chain grate boilers both produce ash. Reciprocating grate boilers use the reciprocating motion of the grate to push the ash to the slag outlet, while chain grate boilers bring the ash to the end of the grate through the continuous operation of a chain belt. Both have mechanized and automated ash handling systems, but with slightly different handling efficiencies and applicability. Chain grate boilers typically produce more ash and require more frequent cleaning, whereas reciprocating grates allow for more even combustion, which reduces ash production and simplifies ash handling.

In addition, both types of boilers require a multi-stage flue gas treatment system to minimize particulate matter and harmful gas emissions. Reciprocating grate boilers may require additional flue gas treatment when handling high ash and high volatile fuels, while chain grate boilers need to keep flue gas treatment equipment operating efficiently during continuous operation.

Regulatory Compliance

Both reciprocating grate boilers and chain grate boilers require strict adherence to national and local emission control regulations and environmental standards in terms of regulatory compliance and environmental standards. The environmental performance of the boilers can be ensured by equipping them with highly efficient dust removal equipment, adopting low-NOx combustion technology, desulphurization devices, and carbon capture and sequestration technology, which can effectively reduce the emitted substances. Regular safety operation training and maintenance programs can further ensure safe boiler operation and compliance. These factors must be thoroughly considered when selecting and operating a boiler to meet regulatory requirements and environmental standards. Due to lower emissions, reciprocating grate boilers are often more compliant with stringent environmental regulations and standards, providing a sustainable option for industries that prioritize environmental compliance.

Cost Analysis

Initial Investment

Reciprocating grate boilers usually involve a higher initial equipment cost. This is because they are more complex in design and contain mechanical devices that reciprocate back and forth. Chain grate boilers typically have a lower initial cost compared to reciprocating grate boilers, which makes them an attractive option for budget-conscious projects.

Operating and Maintenance Costs

Over time, the higher efficiency and fuel flexibility of reciprocating grate boilers can reduce operating costs. However, due to their complex mechanical components, they may require more sophisticated maintenance programs.

Cost-Benefit Analysis

While the initial investment in a reciprocating grate boiler is higher, its long-term cost efficiency and operational benefits can offset the upfront costs, providing better value in the long run. Choosing the right type of boiler should consider factors such as initial investment, long-term operating and maintenance costs, and fuel efficiency. Depending on the specific needs and budget, the optimal decision can be made.

Maintenance Requirements

Chain Grate Boiler Maintenance

Maintenance of the chain grate boiler is critical. To ensure its efficient operation, the chain belt and grate must be cleaned and inspected regularly. Wear and tear of the grate and chain is a common problem that, if not dealt with promptly, may lead to a reduction in the operating efficiency of the boiler or even a breakdown. Therefore, special attention should be paid to the wear and tear of the grate and chain in daily maintenance, and the parts with serious wear and tear should be replaced in time to ensure the normal operation of the chain belt and grate. In addition, the furnace and flue should be cleaned regularly to avoid the accumulation of ash and soot affecting the combustion effect.

Reciprocating grate boiler maintenance

Reciprocating grate boiler maintenance should not be ignored. In order to maintain its smooth and effective reciprocating movement, regular maintenance and inspection is required. The inspection should cover the wear and tear of the mechanical parts, the smoothness of the reciprocating movement, and the possible jamming phenomenon. Once abnormalities are found, timely repair and adjustment should be carried out to ensure the normal operation of the reciprocating grate. Through regular inspection and timely maintenance, mechanical failures can be effectively avoided and the operational efficiency and safety of the boiler can be improved.

Fields of Application

Industries using chain grate boilers

Chain Grate Boilers are a widely used heat source for industrial applications, especially in industries that require a consistent and even fuel supply. In the textile manufacturing industry, chain grate boilers provide a steady supply of steam and heat to meet the needs of weaving, dyeing, and finishing processes. In paper mills, the efficient combustion of chain grate boilers ensures the stable operation of processes such as pulp cooking and paper drying. In addition, chain grate boilers play an important role in chemical plants, providing the necessary heat for various chemical reactions.

Industries that use reciprocating grate boilers

Reciprocating grate boilers are widely used in industries such as waste management, agriculture, and large-scale biomass energy production because of their significant advantages in handling various fuel types. In the field of waste management, reciprocating grate boilers can effectively handle various solid wastes, such as domestic garbage and industrial waste residues, which are converted into energy through combustion, thus realizing the reduction, resourcefulness, and harmlessness of wastes. In the field of agriculture, reciprocating grate boilers can be used for the utilization of biomass energy, such as straw, wood chips, and other agricultural waste combustion for power generation or heating. In addition, in the biomass energy production industry, the high-efficiency combustion and low-emission characteristics of reciprocating grate boilers make them ideal for producing clean energy.

Industry Preferences

Industry preferences for grate boilers vary depending on their specific needs and conditions. Some industries prefer chain grate boilers primarily because of their simple design, ease of operation and low maintenance costs. These industries typically have more consistent fuel requirements and demand higher levels of boiler stability and reliability. Other industries prefer reciprocating grate boilers, mainly because of their excellent combustion efficiency and adaptability to different fuels. These industries often have to deal with a variety of complex fuels and require a high degree of flexibility and efficiency from their boilers.

Summarize

In short, when choosing a boiler type, whether it is a chain grate boiler or a reciprocating grate boiler, several factors need to be taken into consideration.EPCB Boiler is committed to providing boiler solutions that best meet the needs of our customers, based on its deep industry experience and superior technical capabilities. From fuel type to efficiency needs to environmental considerations, EPCB Boiler provides comprehensive and detailed consultation and service. Each boiler type has its unique advantages for different industrial scenarios. By gaining a deeper understanding of these differences and combining them with EPCB Boiler's professional advice, companies can more wisely choose the boiler that best suits their energy needs and achieve efficient, environmentally friendly energy utilization. If you have any doubts about boiler selection, please feel free to contact EPCB Boiler.

FAQ

What is the main difference between a chain grate boiler and a reciprocating grate boiler?

The main difference between chain grate boilers and reciprocating grate boilers is reflected in several aspects. First of all, in the operation mechanism, the chain grate boiler adopts the continuous operation of the chain belt to stabilize the delivery of fuel, to ensure the continuity of the combustion process. Reciprocating grate boilers, on the other hand, through the back-and-forth reciprocating movement of the grate to stir and propel the fuel bed, to achieve more uniform combustion. Secondly, in terms of fuel flexibility, the reciprocating grate boiler can handle more types of fuel due to its unique stirring mechanism, showing higher adaptability. Finally, in terms of combustion efficiency, the stirring design of the reciprocating grate boiler helps the fuel to burn more fully, thus improving the overall combustion efficiency.

Which type of boiler is more environmentally friendly?

Reciprocating grate boilers are typically more environmentally friendly. Due to their higher combustion efficiency, reciprocating grate boilers can burn fuel more fully, reducing emissions of unburned material and harmful gases. At the same time, they are often designed with secondary oxygen supply technology and good sealing performance, which further reduces pollutant generation and better meets strict environmental regulations.

What factors should I consider when selecting a chain grate boiler or reciprocating grate boiler?

When selecting a chain grate boiler or reciprocating grate boiler, a number of key factors should be considered. Firstly, fuel availability is an important consideration as fuel requirements vary between boiler types. Secondly, efficiency requirements are also a decisive factor, as efficient boilers reduce energy consumption and running costs. At the same time, compliance with environmental regulations cannot be ignored, and it is vital to select a boiler type that meets local environmental requirements. Finally, cost considerations are also a non-negligible part of the decision-making process and need to be weighed against initial investment and long-term operating costs. Taking all these factors into consideration, the type of boiler best suited to the specific operational needs and objectives can be selected.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler