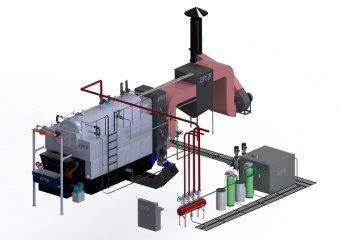

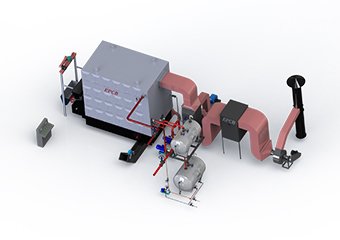

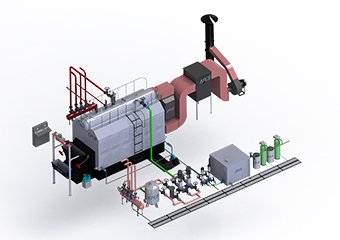

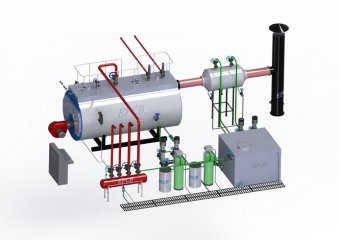

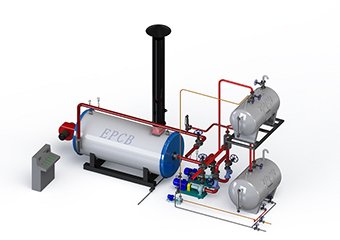

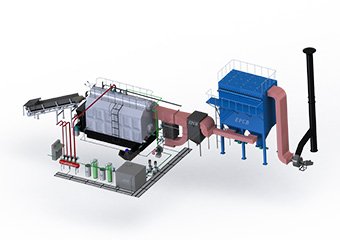

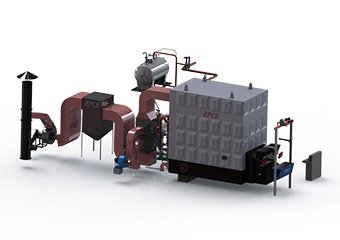

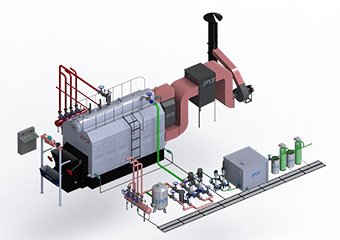

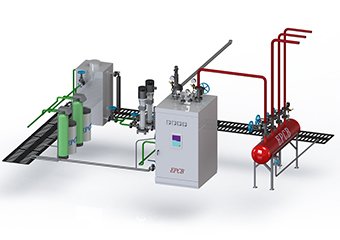

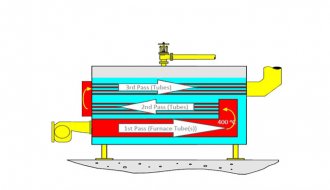

System type: Fuel Saving Three Pass Diesel Fired Steam Boiler

Boiler fuel: natural gas, liquefied petroleum gas, diesel, gasoline, heavy oil, etc.

System features: saving fuel costs , high degree of automation and environmental protection.

Boiler application: Food factory, Textile factory, Chemical factory, Dyeing & Printing factory, etc.