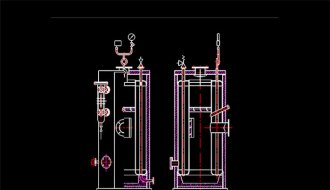

Boiler Type: Vertical Gas Fired Steam Boiler

Capacity: 0.1~ 2T/h

Pressure: 0.4~1.25MPa

Fuel: Diesel, Fuel Oil, Natural Gas, LPG, Furnace Oil, City Gas, Coke Oven Gas, Methane Gas, Biogas, etc.

Application: Textile Mill, Chemical Plant, Oil Refinery, Slaughterhouse, Food Plant, Candy Plant, Beverage Plant, Pharmaceutical Plant, Printing and Dyeing Plant, Machinery Manufacturing Industry, Garment Factory, Laundry…